Experienced Fabricators of HFIC & CVD Equipment

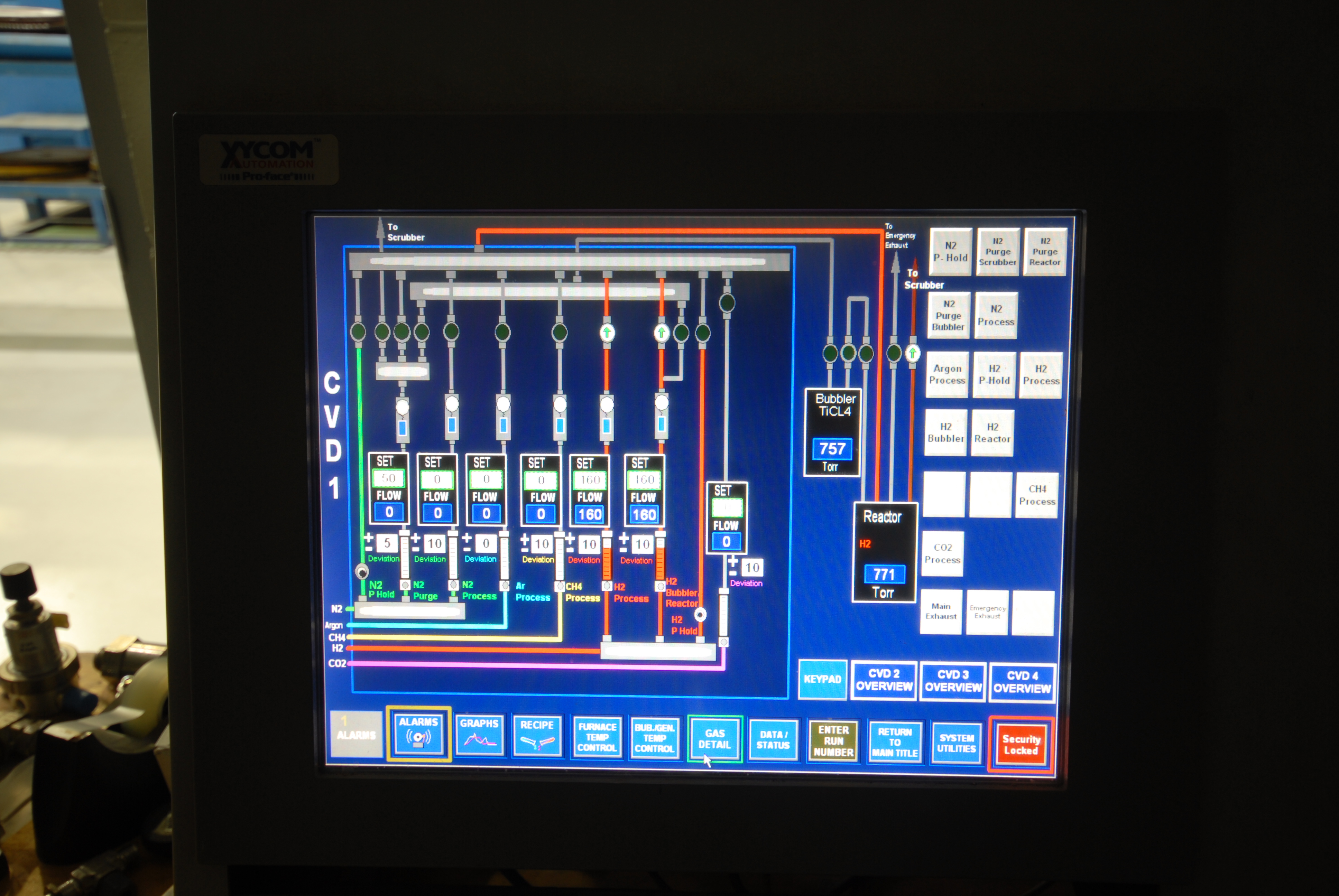

Ti-Coating, Inc. is the recognized innovator and fabricator of HFIC and CVD equipment, configured to meet the needs of today’s industry. The MODULAR HF cleaning system, developed by Ti-Coating, moved the HF cleaning process into the modern century with its modular design and reduced installation time. Our unique designs produce myriad systems and services. Our high-quality equipment is designed for ease of installation, and is robust enough to handle the most difficult cleaning requirement.

Equipment

CHOOSE THE SIZE THAT BEST FITS YOUR REQUIREMENTS

| Ti-Coating Model | WORK ZONE SIZE | |

|---|---|---|

| DIAMETER | LENGTH | |

| #2024 | 20″ (508 mm) | 24″ (610 mm) |

| #3024 | 30″ (762 mm) | 24″ (610 mm) |

| #3038 | 30″ (762 mm) | 38″ (927 mm) |

| #4024 | 40″ (1016 mm) | 24″ (610 mm) |

| #4038 | 40″ (1016 mm) | 38″ (927 mm) |

| #4050 | 40″ (1016 mm) | 50″ (1279 mm) |

| #5040 | 50″ (1279 mm) | 40″ (1016 mm) |

System Sizes ideally suited for small to large repair centers.

Ti-Coatings’ Value Added Services

We provide our clients with exceptional value by delivering state-of-the-art services and systems, and through continued development of products and technologies. Ti-Coating is more than just our superior coatings, cleaning, and equipment; our products and services represent value-added benefits for you.

Our design features a robust and reliable electric furnace, so you don’t lose time or productivity as a result of our equipment.

PARTNER WITH TI-COATING

Why have Ti-Coating build your equipment?

Ti-Coating offers unique designs that mean a cleaning solution of increased efficiency that will save you time and money. Our compact designs are also ideal for locations with limited floor space.