Improving Productivity Through Coatings

Ti-Coating, Inc. offers pioneering thin film coating technology, service and equipment, as well as hydrogen fluoride ion cleaning (HFIC). We continue to improve coating processes – achieving technological advancements that enable our clients to enjoy increased productivity, and allowing us to provide solutions for difficult metal removal and metal forming applications.

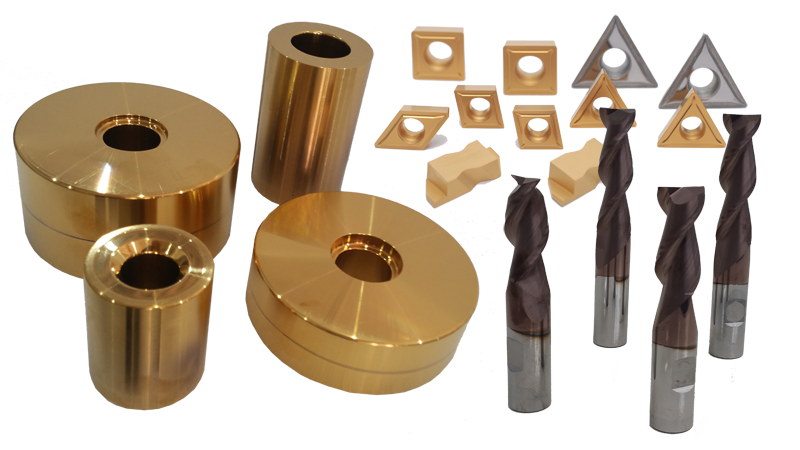

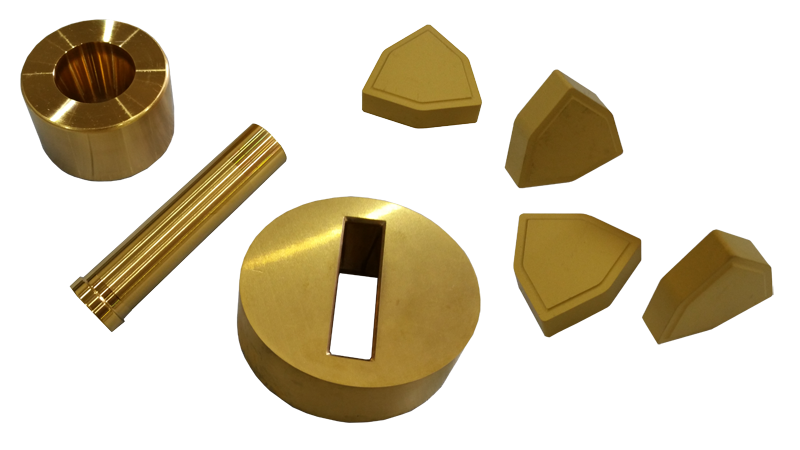

PVD COATING

We utilize the latest technology to produce multi-layered, heat resistant PVD coatings. These coatings provide our clients with tool life that far exceeds standard titanium nitride coatingsPVD (Physical Vapor Deposition) Coating

The reduced temperature of the physical vapor deposition (PVD) process ensures that the metallurgical and dimensional characteristics of the coated part are not compromised. The benefit of this process from Ti-Coating – combined with its dense, fine grain structure – results in a product that features tremendous lubricity, hardness and anti-corrosive characteristics.

CVD COATING

The workhorse of the metalworking industry, CVD coatings provide significant production increases and cost savings on a variety of metal cutting and metal forming applicationsCVD (Chemical Vapor Deposition) Coating

The exceptionally strong bond created by this process, combined with the ability to create multiple layers with relative ease, makes the chemical vapor deposition (CVD) process the workhorse of coating technology.

Ti-Coating CVD coatings are the ideal choice for many difficult metal forming and metal cutting applications.

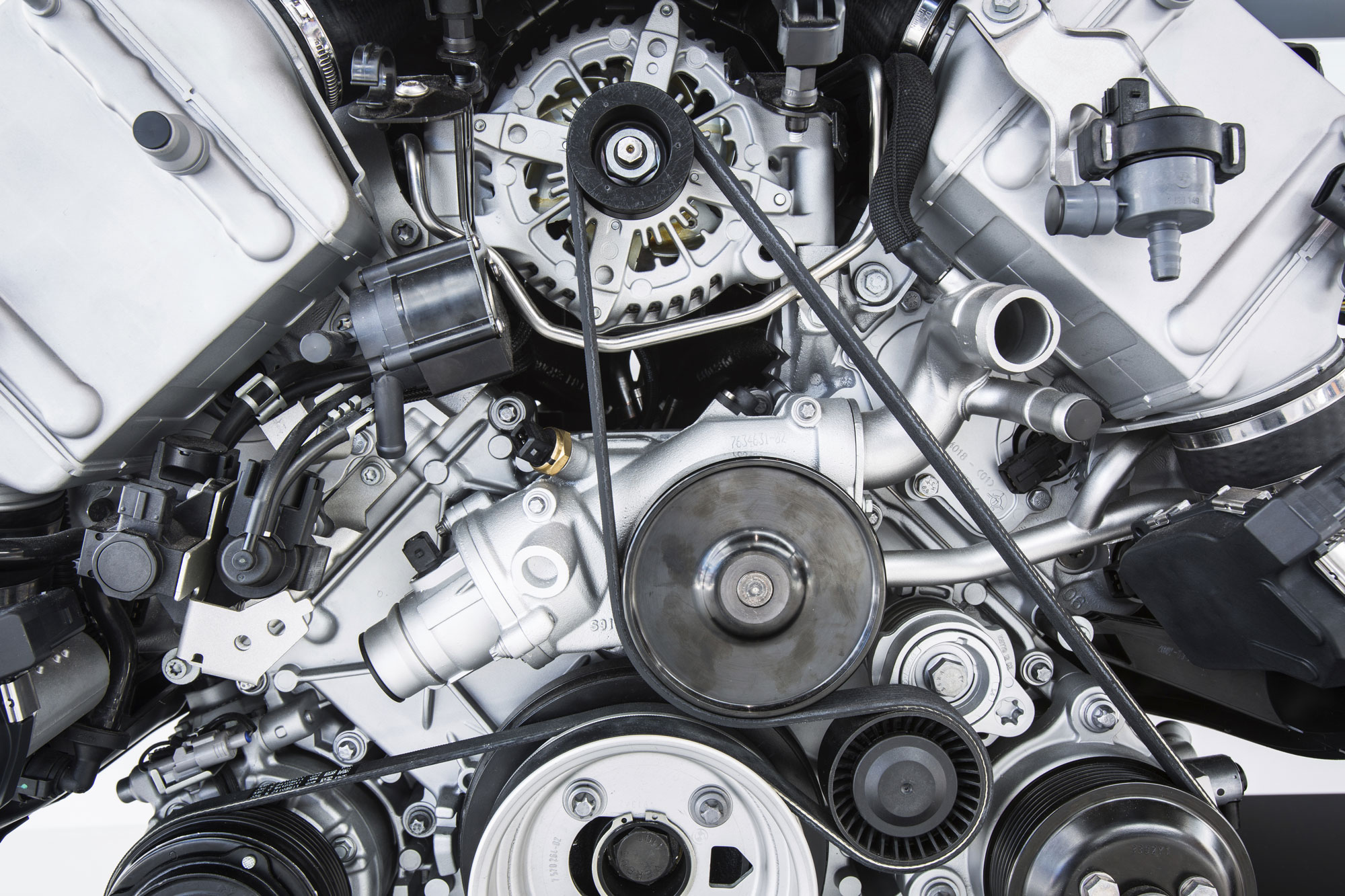

HFIC

Hydrogen fluoride (HF) ion cleaning - an effective & highly versatile, automated process control offers a total cleaning solution with increased efficiency.Hydrogen Fluoride Ion Cleaning

HFIC is used to clean gas turbine superalloys. This is a preparation step for the repair of cracks and other damage found in field-run high-temperature gas turbine engine components. Commonly used in the aerospace and land-based power-generating gas turbine industries, this chemical cleaning is an indispensable step in the braze repair process.

Real People. Real Support. Real Results.

Our coatings, equipment fabrication and services are competitively priced, and we pledge excellent service to our customers. At Ti-Coating, this means a quick turnaround on your job, as well as serving your unique needs. Contact us today to learn more, or to discuss how we can solve your coating, equipment or cleaning problems.